We designed and manufactured the kitchen and dishwasher duct system for the Embassy Suites Aruba Hotel, using BIM modeling, prefabrication in Mexico and international logistics.

Learn more

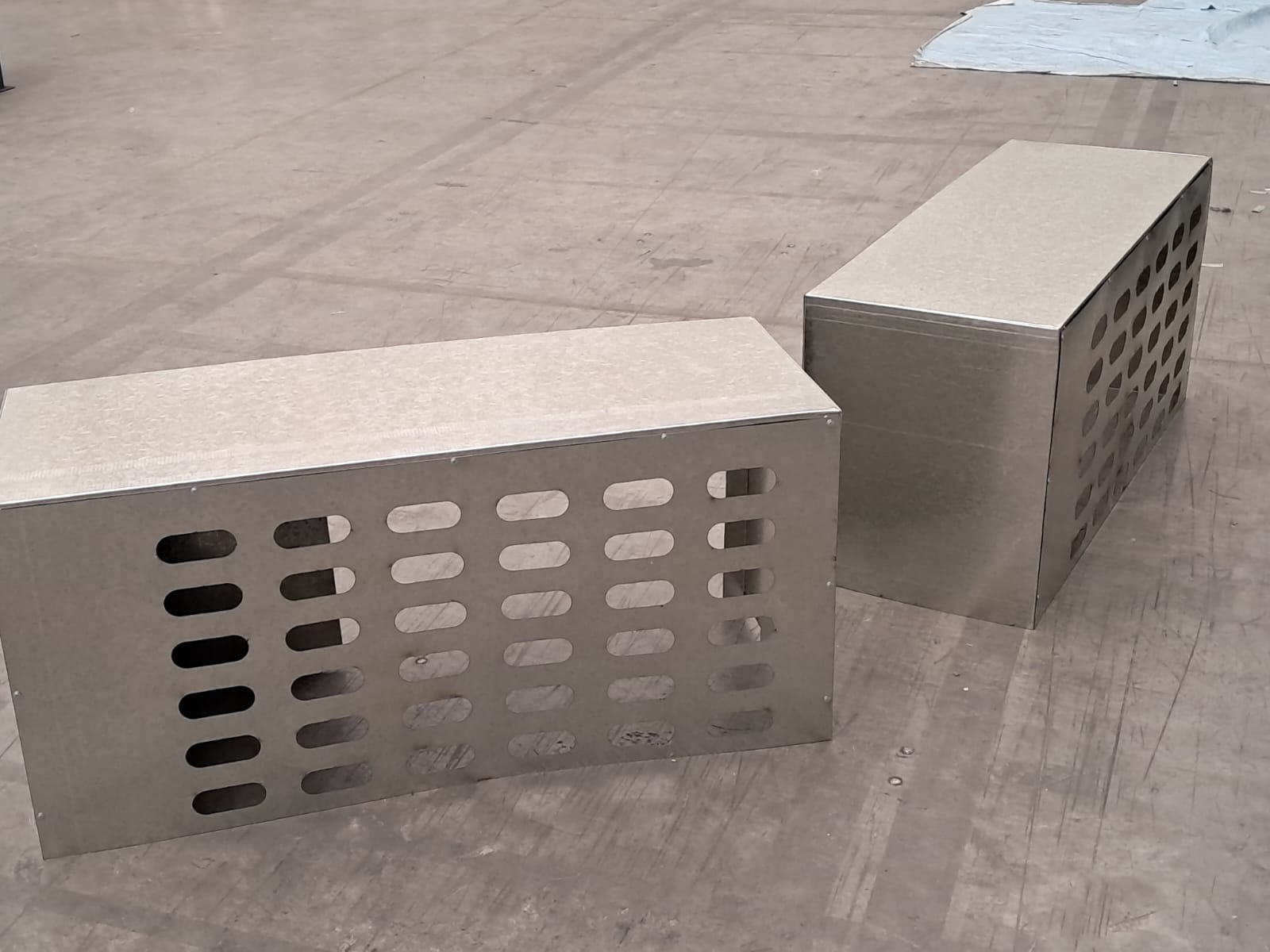

Rectangular Duct Fabrication with Internal Insulation

Project overview

The client requested the fabrication of rectangular grapa-zeta ducts with internal duct liner insulation. The objective was to obtain robust, precise pieces ready to be integrated into an existing HVAC system, ensuring an exact fit on site and a smooth, trouble-free installation.

- Fabricate rectangular grapa-zeta ducts using galvanized sheet metal.

- Apply internal duct liner insulation to improve thermal and acoustic performance.

- Deliver installation-ready pieces within the agreed schedule.

- Controlled prefabrication in our workshop with dimensions verified before dispatch.

- Careful installation of duct liner and internal seals in each section.

- Manufacturing of fabric flexible collars to enable safe, flexible joints on site.

- Faster installation thanks to pieces delivered ready for use.

- Better overall insulation of the HVAC system by integrating duct liner from fabrication.

- Reduced adjustments on site and higher client satisfaction.

Gallery

Technical sheet

| Scope | Fabrication of rectangular grapa-zeta ducts, internal duct liner insulation and fabric flexible collars for connection. |

| Material | Galvanized sheet metal grapa-zeta profile, thermal-acoustic duct liner and industrial fabric for flexible collars. |

| Schedule | Delivery within the agreed timeframe, according to the client’s project schedule. |

Results

Pieces fabricated according to the requested dimensions, with internal insulation installed and delivered within the agreed schedule.

The pieces were received in perfect condition and within the agreed timeframe. The manufacturing and delivery process was clear and efficient.