Ductos cuadrados para espacios eficientes y funcionales

Adaptabilidad en espacios reducidos, excelente sellado y fabricación precisa

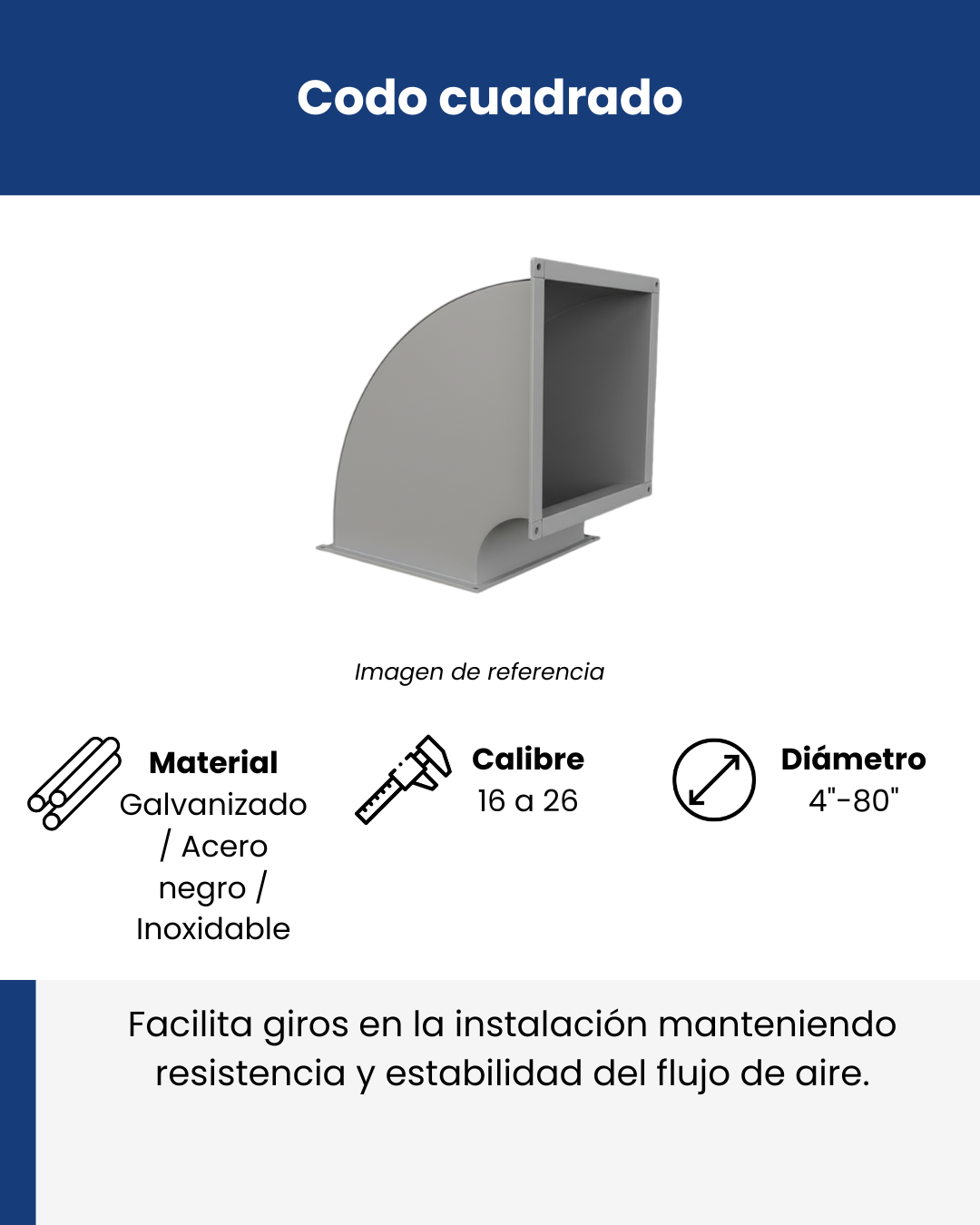

Solicita tu cotizaciónGalvanizado / Acero negro / Inoxidable

16 a 26

4″ – 80″

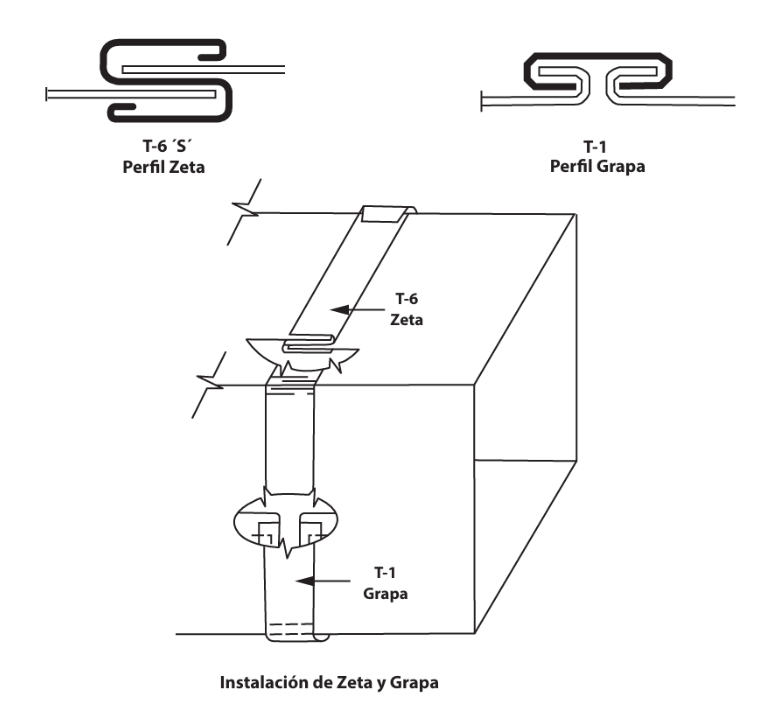

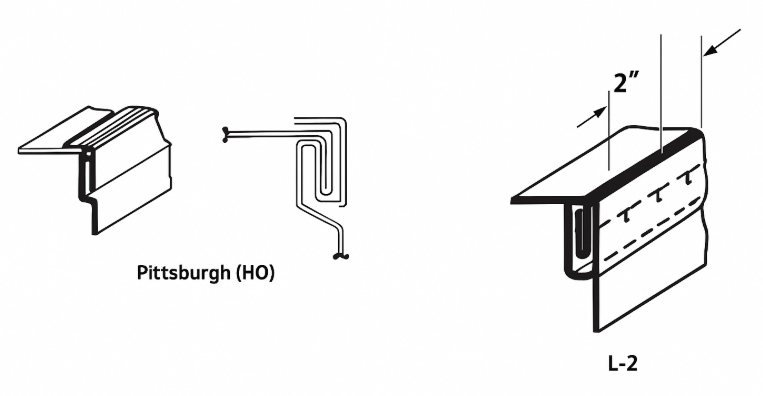

Tdf y grapa Z

¿Por qué elegir nuestros ductos cuadrados?

- Ensambles herméticos que evitan fugas de aire

- Ideal para espacios con poca altura o ángulos cerrados

- Soporta gran volumen de aire

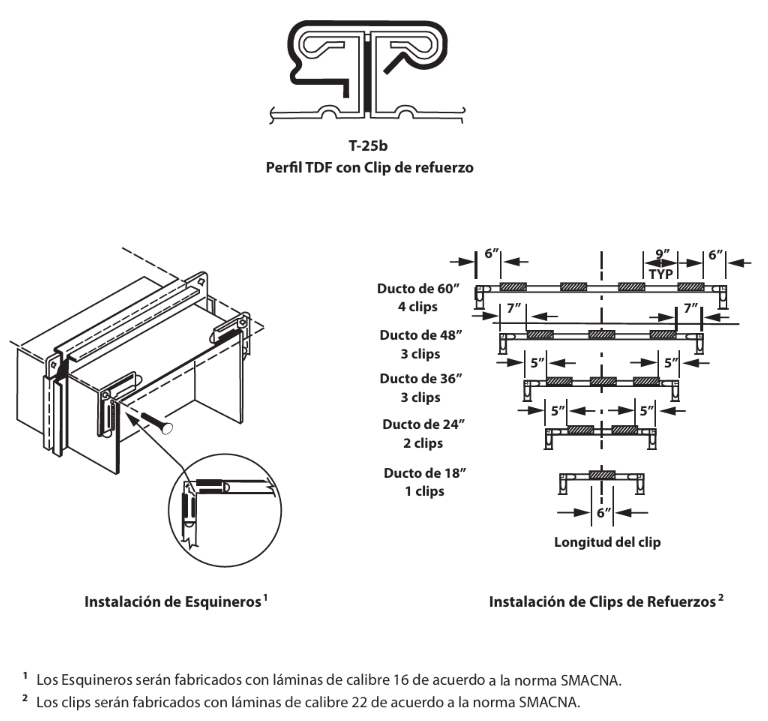

REFUERZOS PARA DUCTERÍA CUADRADA

Los refuerzos para ductería rectangular aseguran la estabilidad y el correcto desempeño de los sistemas en diferentes condiciones de presión. Gracias a su diseño versátil, se adaptan a distintos calibres y dimensiones, manteniendo la forma del ducto y evitando deformaciones. Fabricados en acero galvanizado de alta calidad, permiten instalaciones más seguras y duraderas con un menor costo de mantenimiento.

Diseño inteligente

Se adapta a techos bajos y esquinas difíciles

Menor consumo energético

Mejor sellado, menor pérdida de energía térmica

Ahorro en instalación

Seccionables y fáciles de instalar con conectores tipo TDF o brida

Nuestros productos

Componentes para sistemas de ductos cuadrados listos para tu proyecto

Importante: Estos son algunos de nuestros productos; contamos con más de 500 opciones de productos en el catálogo. Para enviarte una cotización exacta necesitamos las medidas (diámetros, largos, cantidad, etc.). Un asesor te atenderá personalmente.